Compressed Air Design Guide

Additional guidelines to consider when designing a compressed air system include. When youve completed the.

Compressor Inlet Piping Compressed Air Best Practices

¼ HP through 30 HP is a publication illustrated with photos and charts detailing the types of compressors available their intended applications and selection criteria for a variety of industries.

. Optimizing performance to meet actual demand. This best practice guideline identifies the requirements for compressed air systems as pre-requisites in the production and processing including packaging and transportation for safe food and beverage production. This publication provides guidance for designing low pressure compressed air systems with a maximum design operating pressure of 125 psig including piping compressors aftercoolers and separators air receivers and air dryers.

Many factors must be considered when designing a compressed air system to ensure its efficiency reliability and safety. Compressed air is often manufactured on site while other utilities such as electricity natural gas and water are. Designing Your Compressed Air System Air Flow Measurement Kaesers air flow measurement system uses mass flow meters to record the actu-al amount of compressed air being used at any given time.

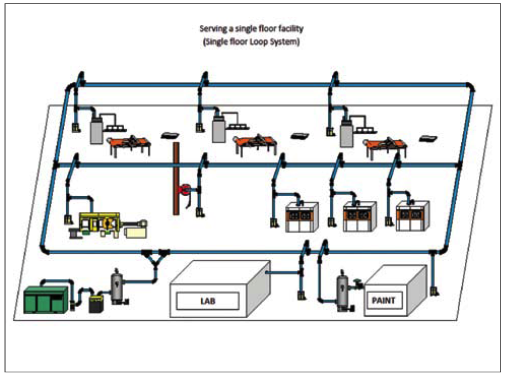

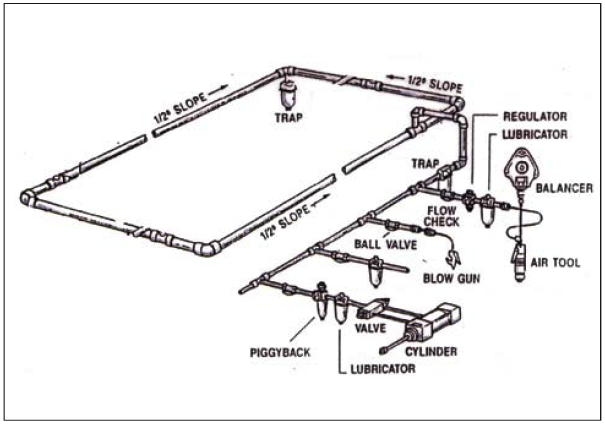

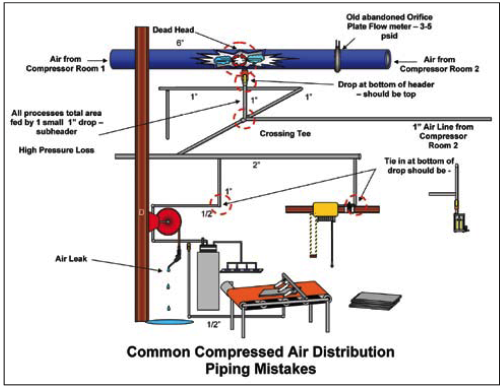

Because suddenly the temperature rise which takes place through air is compressed it that necessary to recipient all tools and equipment work efficiently within are narrow pressure range. Single main pipe layout with branch lines. With the proper knowledge engineers can work alongside compressor manufacturers to ensure that an optimal air compression system is installed There are various factors to consider when designing a compressed air system that help to improve the reliability and efficiency of compressors and ancillary equipment reduce leakage and pressure drops.

Methods for sizing piping are included. The ISPE Good Practice Guide for process gases asserts that compressed air usage in pharmaceutical manufacturing should be free from contaminants and routinely maintained and tested. Proper design should allow for adequate cooling and ventilation of.

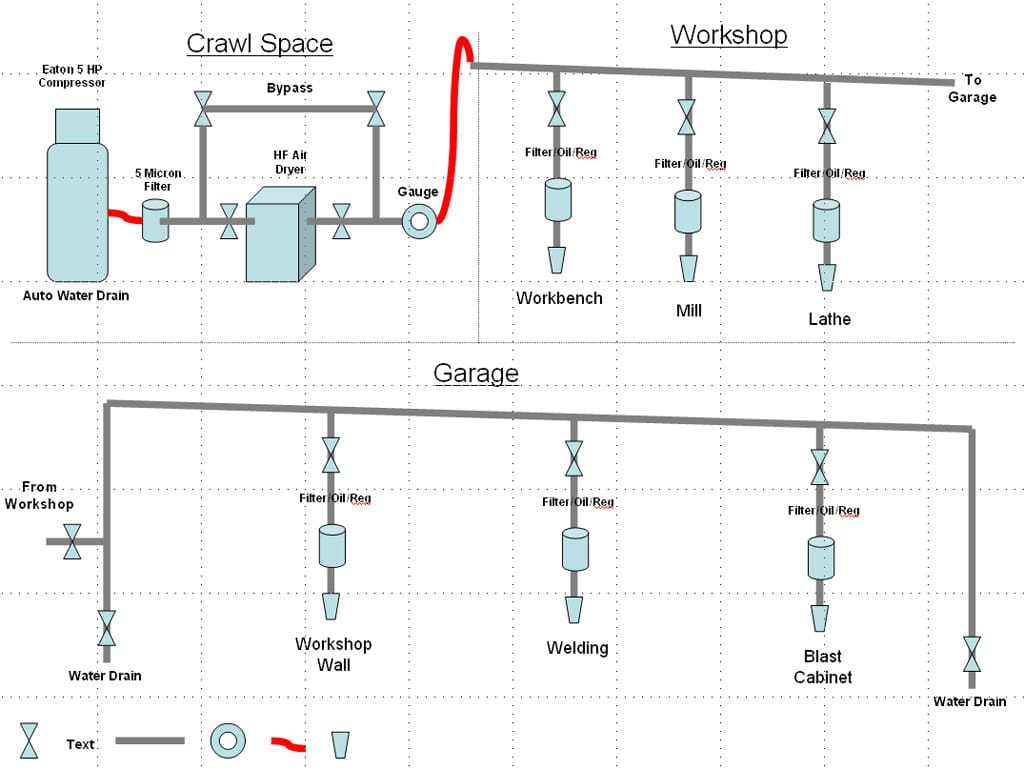

I use it to run all manner of hand held air tools a blast cabinet and its very important for the CNC Machines in my shop to have clean dry compressed air. Fundamentals of compressed air production. Design of an Air Compressor.

Our drag-and-drop features give you complete control over your design. Although there are not specific limits set the ISPE Good Practice Guide does provide helpful suggestions recommendations and guidelines for adequate system. If your compressed air piping design is not well done your energy costs will go up your equipment may fail.

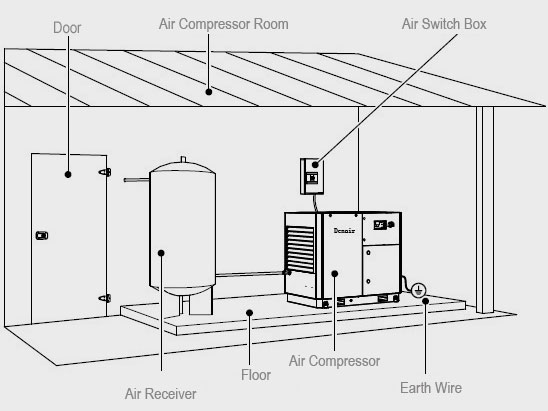

Compressed air usage and potential savings for the typical compressed air user. Gimme some air please. COMPRESSED AIR SYSTEMS 51 General 511 A compressed air system may consist essentially of one or more compressors with a power sourcecontrol system intake air filter aftercooler and separator air receiver air dryer and inter connecting piping plus a distribution system to carry the air to points of application.

However designing a compressed air system is more difficult than you might imagine the compressed air has to be delivered with sufficient volume good enough quality and enough pressure to power the components that require compressed air. I love having air conveniently available in my shop. Flow meters can be inserted into compressed air piping without interrupting system production and output standard signals to a recording.

Rotary Air Compressor Selection Guide presents the. Compressed air is widely used as a power source in industry to power tools in many types of conveyors in manufacturing and converting processes and in filtration refrigeration and aeration processes. This chapter will focus on the roles that the following system parameters play in achieving the ultimate goal of a well-designed.

Compressed air system design The planning and design of an air piping system are crucial steps to ensure optimal performance of pneumatic equipment and tools. Basic Principles Tips and Suggestions. In order to improve your knowledge of compressed air and guide you in your projects we provide you with reference guides and instructional videos on compressed air systems.

Sizing and selection Compression principles Flow and pressure units Receiver tank Air dryer and filtration selection Compressor room ventilation Cooling water Compressed air piping network Monitoring and control. Low Pressure Compressed Air Systems Design Guide. 512 The object of installing a compressed air system shall be to.

Energy Efficiency Best Practice Guide Compressed Air Systems. 8 rows This guidebook addresses the typical compressed air systems common to most small and medium. This system design engineering guide covers the fundamentals of compressed air technology and highlights ways to improve efficiency in a compressed air system.

RapidAirs System Designer is a free 3D drawing tool that will help you easily create a compressed air piping system for your facility or workshop. Compressor costs over a ten-year lifecycle. ¼ HP through 30 HP.

This system design engineering guide covers the fundamentals of compressed air technology and highlights ways to improve efficiency in a compressed air system. Shop Air Compressor System Design Plumbing Complete Guide I Love Shop Air. Ad Buy Air Compressors Online.

Whenever possible the compressor should be located in a clean temperature controlled and well lighted environment with sufficient clearance to allow for servicing of the unit and removal of major components. Dry compressed air at a stable pressure to every end user within the compressed air system at the lowest cost possible. 352 Placement and design 85 353 Foundation 85 354 Intake air 85 355 Compressor room ventilation 86 36 COMPRESSED AIR DISTRIBUTION 89 361 General 89 3611 Air receiver 89 362 Design of the compressed air network 90 363 Dimensioning the compressed air network 90 364 Flow measurement 93 37 ELECTRICAL INSTALLATION 94.

Compressed air usage and potential savings for the typical compressed air user. It also identifies the air purity requirements for compressed air for both direct and indirect product contact. Air Compressor Selection and Application.

Air Compressor Selection and Application.

Air Piping Layout Plumbing Layout Air Compressor Shop Building Ideas

Compressed Air Basics Webbikeworld

Shop Air Compressor System Design Plumbing Complete Guide

How To Choose An Air Compressor According To Science Applications Maintworld

Compressor Inlet Piping Compressed Air Best Practices

Process Design Of Instrument Air System Instrumentationtools

Air Compressor System Installation Guide Air Compressor Industrial Air Compressors Denair Compressor

Compressor Inlet Piping Compressed Air Best Practices

Search Air System Tenders Tenders By Air System Tenders For Air System Private Tenders In Air S Garage Workshop Garage Workshop Layout Garage Workshop Plans

0 Response to "Compressed Air Design Guide"

Post a Comment